Cargo and Freight

Hybrid airships make it possible to affordably deliver heavy cargo and personnel to remote locations around the world and provide cost effective transportation compared to conventional ground cranes and heavy lift helicopters. Burning less than one tenth the fuel of a helicopter per ton, producing less noise and having lower emissions than aircraft currently in operation. This aircraft will redefine sustainability for the future.

With the ability to access isolated locations around the globe, the hybrid airship can safely and sustainably support a wide range of operations in areas with little to no infrastructure unlike current methods that irriversabily damage the local environments.

The hybrid airship is also able to carry cargo loads and personnel in and out of remote areas daily, not just during certain seasons or only after major road, rail or airport infrastructure is developed.

Internal Payload

The hybrid airship will be capable of carrying more than 21 tons of cargo, upto 19 passengers and two crew members.

The spacious flight deck (labelled crew station and storage bay) can seat up to 19 passengers. The fuel and equipment bay is located directly behind the flight deck and has a fuel capacity of 5,400 litres with a range of 1,900 nautical miles, and can cruise at a speed of 60 knots.

The cavernous cargo bay is at the rear of the gondola, which can hold up to 21,000 kilograms (21 tonnes) of payload and is bigger than the cargo box of Lockheed Martin’s C-130 Hercules transport aircraft.

Cargo Capability

The hybrid airship is able to carry loads that most traditional aircraft cannot. Depending on the dimensions of the load, it can be carried internally or if the load is too large for the cargo bay it is possible to use the hybrid airship as an aerial crane using long cables or slings.

Due to this we are able to access places where road vehicles could not access, which means we can relocate large equipment in remote and otherwise inaccessible locations and can do so with little to no disruption to the local environment.

The versatility of the hybrid airship also allows it to be adapted for different operations or loads. This allows for a variety of underslung load lifting projects, whether the task involves an emergency response to a situation such as a land slide, or a pre-planned airlift to deliver materials to an inaccessible location. An example of how the hybrid airship can be adapted for different loads can be found on our Wind turbine page.

Hybrid Airship vs Heavy Lift Helo

Positioning the LMH1 as a direct replacement for medium and heavy lift helicopters is the first, natural market opportunity. In the simplest terms, an LMH1 can perform 9 out of 10 tasks done by helicopters such as the S64 Skycrane or the CH47 Chinook, and it can do it bigger, safer and with much less cost. The cost benefits can be illustrated most clearly with a direct cost comparison by flight hours ($/hour) and the cost to move one ton, one mile ($/ton-mile). Costs per ton-mile comparisons give us a way to understand the specific cost of completing a task. Hourly cost comparisons give us a way to understand how and why one aircraft type has a cost benefit compared to another.

Cargo movement using helicopters is viewed as last resort due to high cost. In general the purchase price of a heavy lift cargo helicopter (Chinook CH-47, Sikorsky S-92, EC 225 and Erickson Skycrane) are comparable to that of the Hybrid airships at $30-$40M, with maintenance costs that vary based on up-time, but range $3-$5 mm annually depending on use. Fee structures for customers include fixed monthly or annual fee to reserve capacity, and/or hourly fees based on hours flown (varies significantly based on helicopter type). Project management and team mobilization can cost up to $125,000 per project.

Hybrid Airship vs Boeing 737

Do we want to compare the aircrafts?

Additional Information

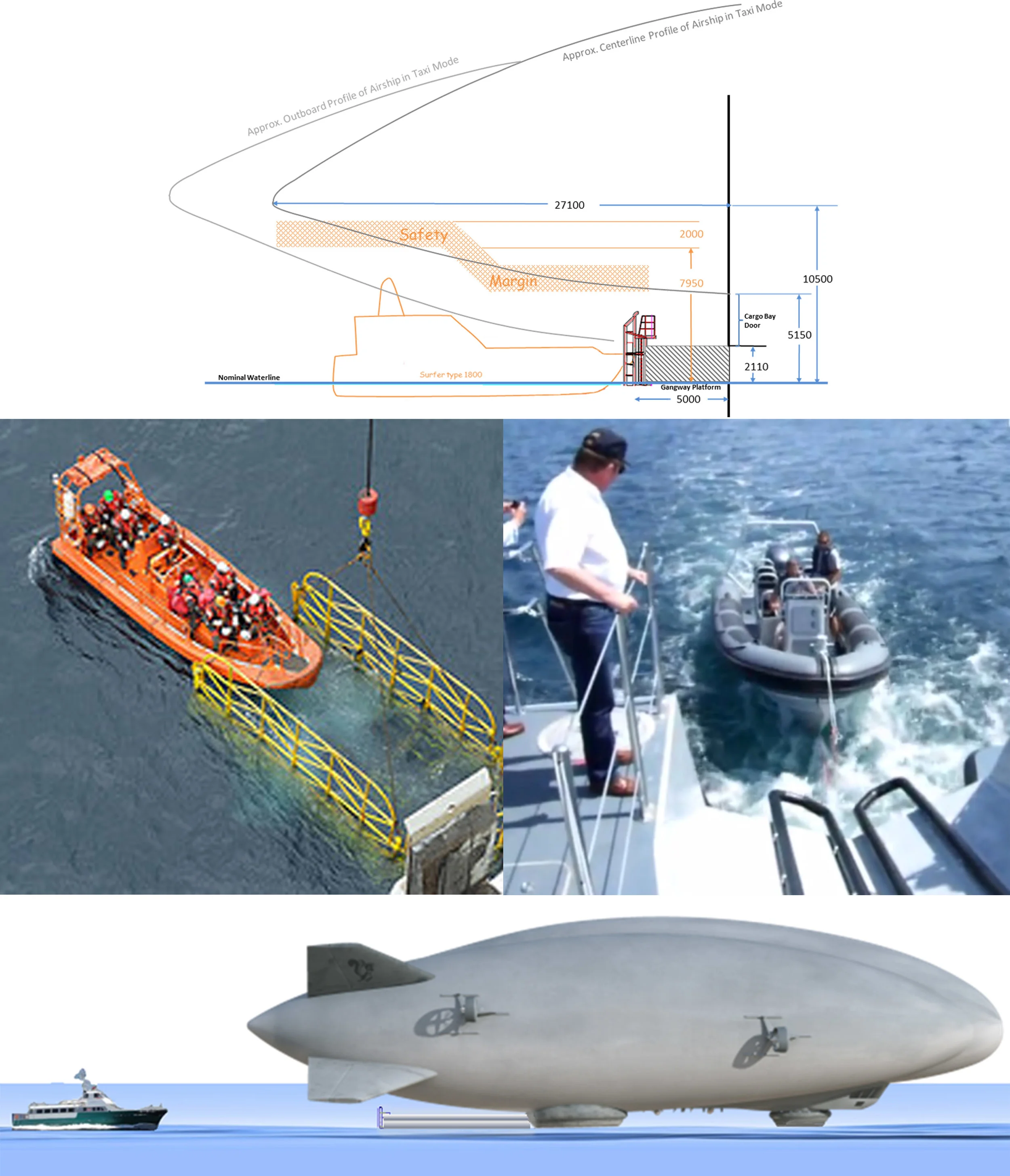

Rigid Inflatable Boats (RIBs) launched out of the Hybrid Aircraft rear cargo door offer the opportunity to deliver personnel and cargo to offshore platforms in regions where wind and sea-state are reasonably calm.

The boats range in size from 12 passengers to 75 passengers, typically operating within 200 miles of a major port facility, delivering people and small cargo to the off shore oil fields where there are more than a dozen platforms and rigs in operation. The boats would remain in use within the oil field area to move the people and cargo from the small HA to the platform.

The HA would be in taxi mode with the thrusters engaged to maintain position with the nose into the wind. The boat would mate with the boarding ladder and push against it to maintain a hard connection. Passenger and small cargo would be moved off or onto the boat. Upon completion of the movement, the boat would back away and return to the platform, the gangway would be pulled back into the cargo bay and the HA would return to its home base.