HYBRID Airship

TECHNOLOGY

Sir Richard Branson: ‘Hybrid airship technology represents an important and exciting aviation milestone.’

Hybrid airships are a completely new type of hi-tech, heavy-lift aircraft that offers a dramatically less expensive and an environmentally friendly alternative to traditional modes of cargo and passenger transportation.

With the ability to take off and land nearly vertically, hybrid airships can operate in the most remote and inaccessible locations without any of the infrastructure needed to support conventional air transportation.

At first glance, because of their immensity and shape, hybrid airships may bear some resemblance to the airships of old but that is about as far as any real comparison can be made - economically, environmentally and technologically the hybrid airships are highly advanced aircraft.

Technologically Advanced

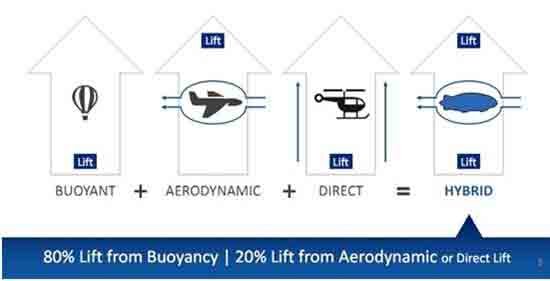

Hybrid airships design combines all the best characteristics of fixed wing aircraft, helicopters and hovercraft with cutting-edge aerospace technology, in an aerodynamically shaped envelope with no rigid structure and filled with non-combustible helium.

Hybrid airships are heavier than air; approximately 80% of their lift comes from buoyant helium and 20% from the aerodynamic lift generated by the shape of the hull and ‘vectored thrust’ from the craft’s four rotatable engines.

Hybrid airships feature a wide range of state-of-the-art avionics, flight controls and navigation systems.

These inherent design characteristics of the hybrid airships provide unique advantages:

No need for a runway or prepared landing surface - hybrid airships can operate from unprepared ground, sand, snow, ice, and even water;

Provide a stable vibration-free cargo bay and passenger compartment environment that lends itself to use as a platform for multiple aerial sensors and imaging equipment;

Due to its unique design and aerostatic characteristics, the hybrid airship is considered one of the safest aircraft available today;

The first airship to utilize the Air Cushion Landing System ACLS which enables operations to/from unimproved, very low infrastructure terrain by using hovercraft technology;

Large cargo capacities

Significant reductions in fuel consumption compared to other air vehicles such as the heavy lift helicopters;

Faster than land and sea transportation system.

Environmental Benefits

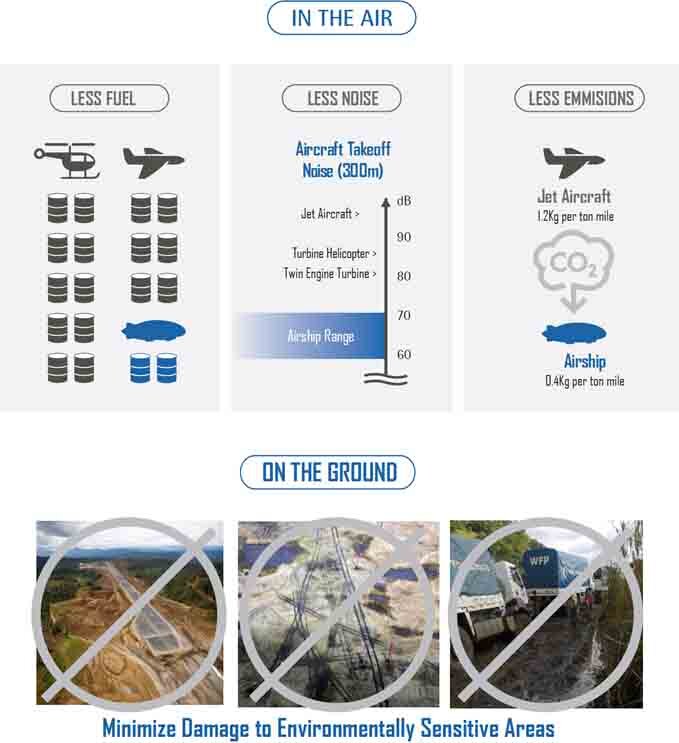

Hybrid airships provide an environmentally green alternative to using heavy-lift helicopters by producing a fraction of the carbon emissions at around one tenth (1/10th) of the cost per nautical ton-mile. In addition, hybrid airships reduce the need for environmentally damaging road and rail lines to be constructed through thousands of miles of remote and unspoiled areas of wilderness which permanently scars the landscape.

Hybrid airships low fuel consumption – about one tenth that of heavy-lift helicopters – greatly reduces their carbon footprint.

Hybrid airships are quiet and unobtrusive to operate compared to helicopters and conventional aircraft.

In short, hybrid airships and Straightline Aviation offer the kind of breakthrough, highly cost-effective and environmentally friendly air transport alternative that the rapidly developing world desperately needs.

Remote Operating Infrastructure

Current remote location infrastructure costs can run anywhere from tens of millions of dollars to billions. In many instances these costs are prohibitive, and without significant inward investment remote communities are left cut off from the world.

Hybrid airships enable year round deliveries to remote communities of essentials such as food, fuel and medicines, reducing product costs and risk of shortages when resupply is impossible via existing transport routes due to adverse weather conditions.

Operating from a variety of surfaces including unprepared ground, desert, snow, ice and even water, without the need for infrastructure.

Payload

The hybrid airship is capable of carrying more than 21 tons of cargo and up to 19 passengers and two crew.

The spacious flight deck and up to 19-seat passenger cabin sit atop the forward ACLS pad, which dictated the large size of that section of the gondola.

The hybrid airships fuel and equipment bay is directly behind the cabin, and the cavernous cargo bay is at the rear of the gondola. The 18 x 3.2 x 3-meter compartment can hold up to 21,000 kilograms (21 tonnes) of payload, and is a little bigger than the cargo box of Lockheed Martin’s venerable C-130 Hercules transport aircraft.

It has a fuel capacity of 5,400 litres with a range of 1,900 nautical miles, and can cruise at a speed of 60 knots.

Mission Capable

Hybrid airships do not need airports: They can operate safely from unprepared flat surfaces whether it is grass, dirt, sand, snow, ice or even water.

Hybrid airships are marginally heavier than air, which makes for excellent ground handling characteristics.

Hybrid airships lift up to 20 tons of freight (future variants will carry many times this amount) plus 18 passengers, or up to 48 passengers in an all-passenger configuration.

Hybrid airships have extended range enabling them to reach and land in remote destinations inaccessible to helicopters and fixed wing aircraft.